Product Description

Surface Condensers / Heat Exchangers

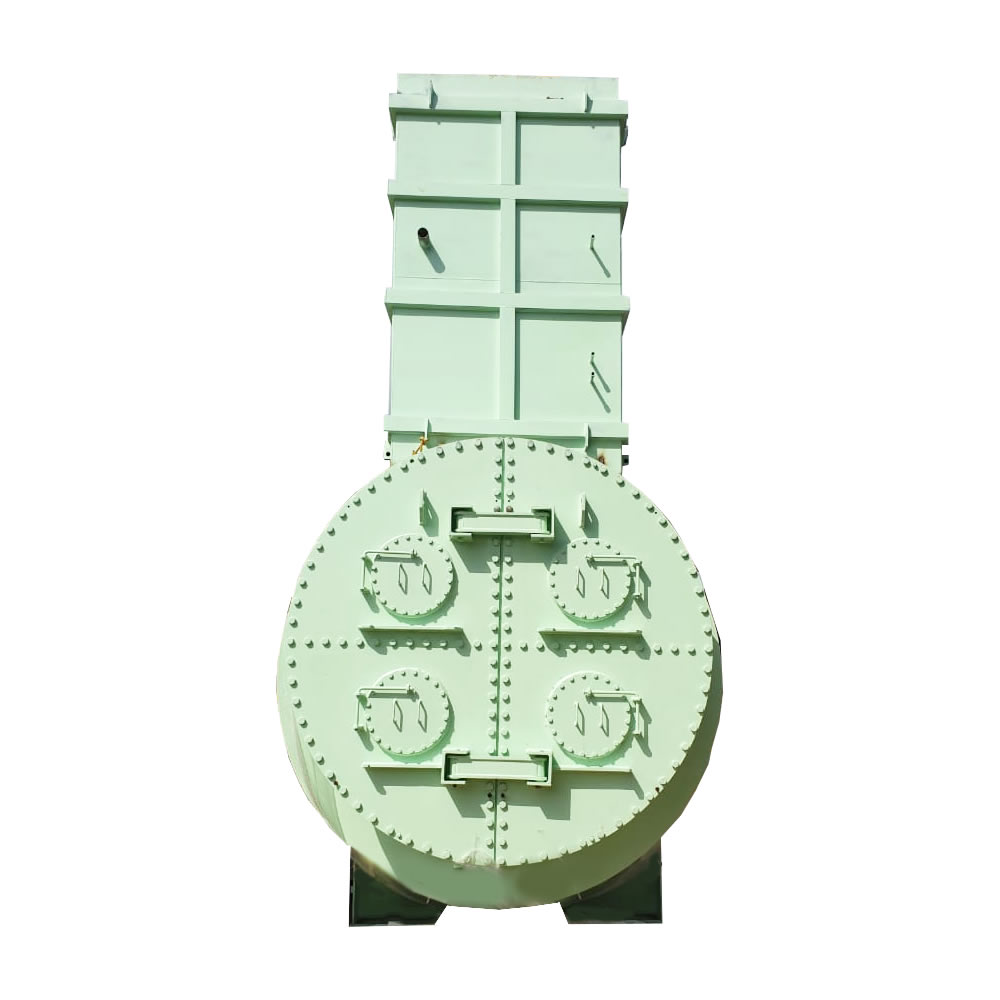

Surface Condensers

New Field’s Surface condensers are designed as per the Heat Exchanger Institute Standards and we also fulfill our client’s specifications & special project Requirements.

New Field has more than 10 years of experience in designing and manufacturing of surface condensers suitable for turbines up to 40 MW. New Field’s Circular condenser design is compact and easy to transport/ship.

Our condensers are manufactured in house at our workshop in Baroda. All the fabrication facilities are in line with the ASME codes and workshop is approved by renowned consultants/ inspection agency.

Barometric Condensers

The Barometric Condenser is employed in a variety of industries as an economical means of removing air, exhaust steam, and other vapors from vacuum equipment. It has been used for decades in the food industry, textile and pharmaceutical industries. Other industries using the Barometric Condenser include the alcohol plants and distilleries, pulp and paper mills, refineries, salt manufacturing plants and a large variety of chemical plants. Thus the Barometric Condenser is found in almost every area of the chemical and process industries which use vacuum stills, calandria pans, multiple-effect evaporators, vacuum crystallizers and high vacuum water and process cooling equipments.

A principle feature of the Barometric Condenser is that the injection water may be discharged through a tail pipe by gravity without requiring a pump. Another advantage of such condensing equipment is its immunity from flooding, in the event of priming or liquid entrainment. In most plants, the vapor exhaust connections of vacuum apparatus are located at considerable elevation above the ground level. The Barometric Condenser permits shorter vapor exhaust lines and provides two additional advantages: a reduction in leakage hazard and lower initial capital cost. Since there are no moving parts, maintenance is low. The condenser requires very little space and is readily installed.

BASIC TYPES

Barometric Condensers are of two basic types:

- Concurrent or parallel flow, in which the vapor to be condensed enters at the top of the unit and flows in the same direction as the water.

- Counter-current or counter flow, in which the vapor enters near the bottom of the equipment and passes upwards against the water flow.

Injection water is delivered in the form of jets, sprays, water curtains or a combination, depending upon the service required.