Product Description

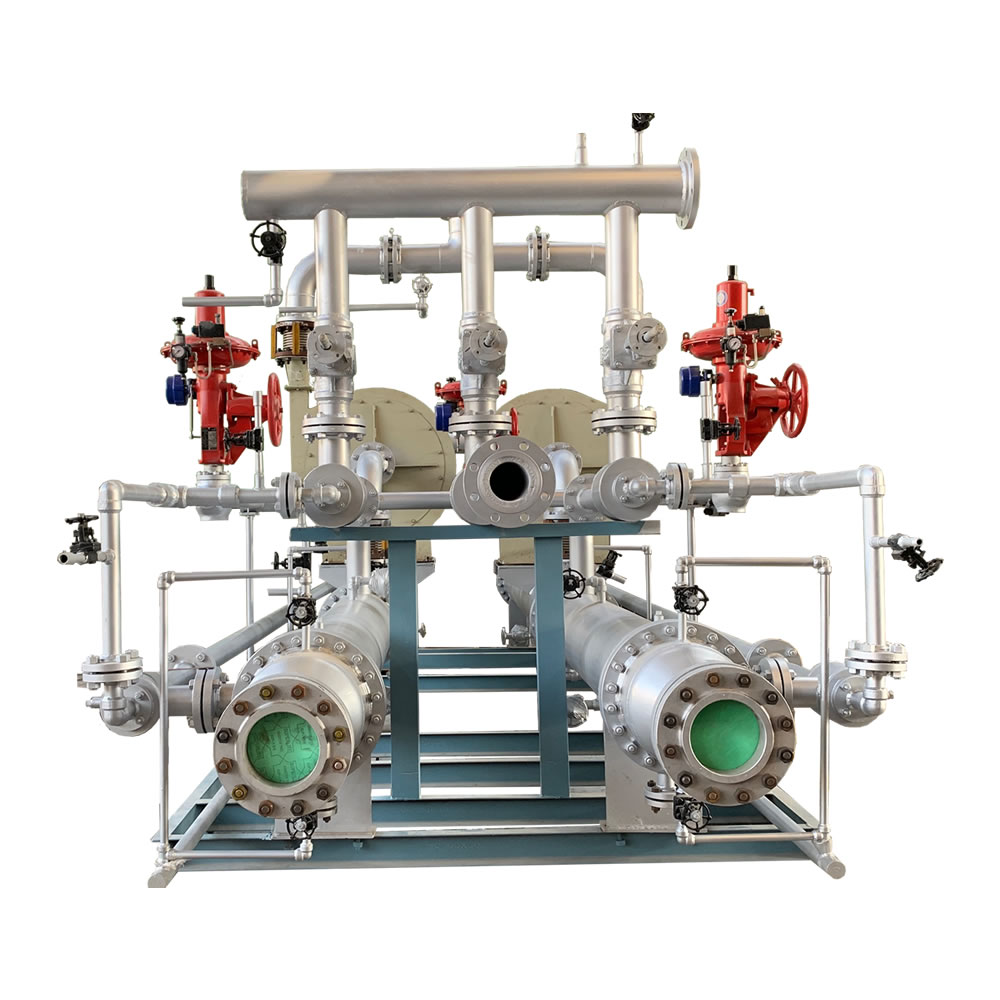

Ejectors & Ejector System

Ejectors uses water as the motive force. The induced fluid is entrained and condensibles are condensed. The non condensible gases are then compressed in the diffuser and discharged into a constant level water sea tank against atmospheric pressure. Maximum absolute pressure obtained by these types mainly depends on the temperature of water or motivating fluid. These units with water at 30 C can attain an absolute pressure of 32 – 40 mm Hg at shut off and with chilled water at 3 C as motivating fluid it can attain 5 – 10 mm Hg. Generally absolute pressure at shut off nearly equals the vapour pressure of the operating liquid at operating temp. These units are most economical where condensible vapours are to be handled.

- Single jet low level

- Single jet barometric

- Multi jet low level

- Multi jet barometric

- Accessory equipment

- Design standards and codes

- Laboratory water jet ejector

Material of Construction

Generally they are constructed from C I with gun metal nozzles, carbon stel, stainless steel, F R P , carbon, P V C, Poly Propylene and rubber lined.

Low Level Steam + Water Ejector

They are used in various industries like food processing; petrolium and others to produce low suction pressure as required by many production operations and laboratories.

Water Ejector

- One Stage Steam + Water Ejector

- Two Stage Steam + Water Ejector

- Three Stage Steam + Water Ejector

- Four Stage Steam + Water Ejector

Steam Jet Ejectors

Single Stage and Multistage Steam Jet Ejectors

Single stage steam jet ejectors are used to create vacuum covering 40 mm Hg. Absolute.

Material of Construction For Ejectors

Vacuum Up to 40 MM Hg Absolute

Two stage Ejector with Condenser

The system is the assembly of two units whose construction is similar to single stage with inter condenser (direct contact type or surface type).

Steam of the first stage is expanded through nozzle entrains the air or other gases and discharges them to diffusers at a higher pressure in the condenser. The discharge from the first stage will then directed to condenser which reduces volume of discharge gases. These gases turn discharged with the help of second stage ejector. The ejector is required to be placed at sufficient height to drain the ejector condenser barometrically. If barometric installation is not possible then an extraction pump is provided to drain the condenser in vacuum. The discharge of exhaust steam and entrained gases is directed to the atmosphere or can be condensed by an after condenser or lead to a water tank if required.

Absolute Pressure Range

Vacuum from 100 MM HG Absolute to 10 MM HG Absolute

Three Stage Ejector is similar in construction as of Single Stage Ejector, but having intermediate condensers. Three Stage Ejector comprises of Booster Ejector, Booster condenser and a Two Stage Ejector. And Two Stage Ejector consists of a high vacuum ejector, a inter condenser and a low vacuum ejector.

This system will give higher vacuum and can handles larger quantity of condensable vapors.

Gas or Gas vapor mixture is discharged from the first stage into the condenser where the operating steam is condensed and gases are cooled. The cooled gases are then entrained by the second stage and discharged into the second inter condenser. Here, the steam used in the second stage is condensed. The gases are finally entrained by the third stage and discharged to atmosphere.

Absolute Pressure Range

Vacuum from 5 MM HG Absolute to 15 MM HG Absolute

Four Stage Ejector with Condenser

Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector.

The Four Stage Ejector consists of following components:

- Primary Booster Ejector

- Secondary Booster Ejector

- Booster Condenser

- Vacuum Ejector

- Inter Condenser

- Low vacuum Ejector

Absolute Pressure Range

Vacuum from 0.5 MM HG Absolute to 5 MM HG Absolute

Five Stage and Six stage Steam Jet Ejectors With Condensor

Five stage and six stage ejectors are designed for absolute pressure in Micron Range. The arrangement of these ejectors is similar to the four stage ejector with additional one or two non condensing stages.

Absolute Pressure Range

In Micron as per customer requirement.

Special Precautions while measuring low Absolute Pressures

- Do not use spring type vacuum Gauges

- Ensure that the guage tubes are clean and free from contamination

- Ensure that the guage liquid is clean and free from contamination

- Barometer should be located near mercury manometer

- Use a suitable macleod gauge with dry mercury and clean ice freezing trap to measure absolute pressure below 1 mm Hg.